What is electrostatic discharge?

ESD stands for electrostatic discharge. ESD is the sudden release of electricity between two electrically charged objects. The transfer of electrons from one surface to another can be a result of walking, rubbing, sliding or separating a material. Simply walking over a carpet can create static electricity, or through contact with a person’s clothing for example. Touch a metal door handle and ouch, we can sometimes feel a shock! Many different surfaces conduct static electricity and this needs to be controlled. You can’t see the transfer of an electronic current – it is an invisible threat.

Who needs to be concerned about electrostatic discharge?

Some manufacturing facilities, such as those environments where electronic parts are produced, or data centres housing mainframe computers, have to be especially careful in controlling electrostatic discharge as it can cause considerable, very often permanent damage. It is not just electronic components that need to be protected; employees also need protection from static discharge. There is also the danger that flammable materials, such as chemicals or gases could ignite, if they come into contact with an electrical spark.

Many environments are at risk and that is why ESD matting, or static-dissipative matting either for the floor or workbenches is so essential. Such products are effective in controlling ESD, primarily for protecting sensitive components as well human operatives. They help to drain/draw the static charge to ground but must be either ‘static dissipative’ or ‘conductive’, and grounded to earth through accessories such as heel grounders, wristbands and cords, to be effective. Very often conductive matting is used on work surfaces, as it draws the electrical current away from the component quicker, moving the static charge efficiently to ground. Beware of matting described as ‘insulative’, as this is not ESD safe.

What ESD matting should I use?

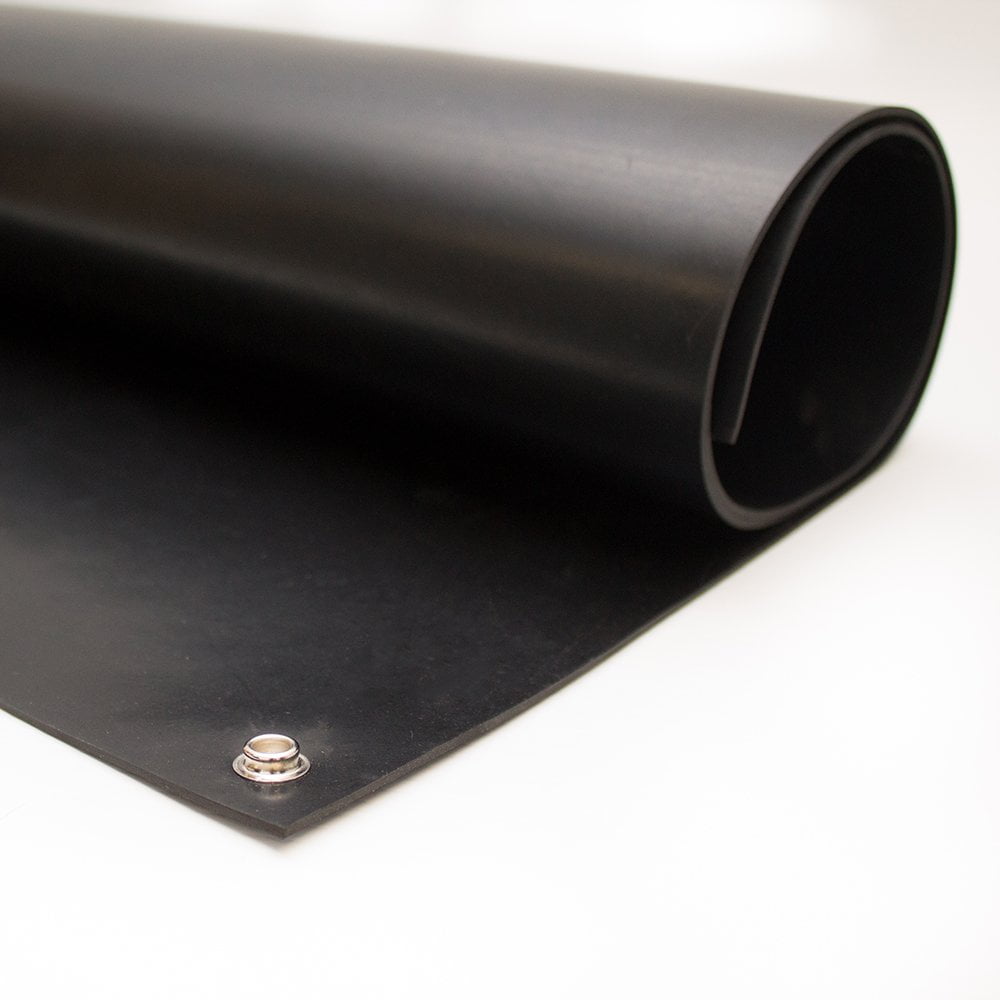

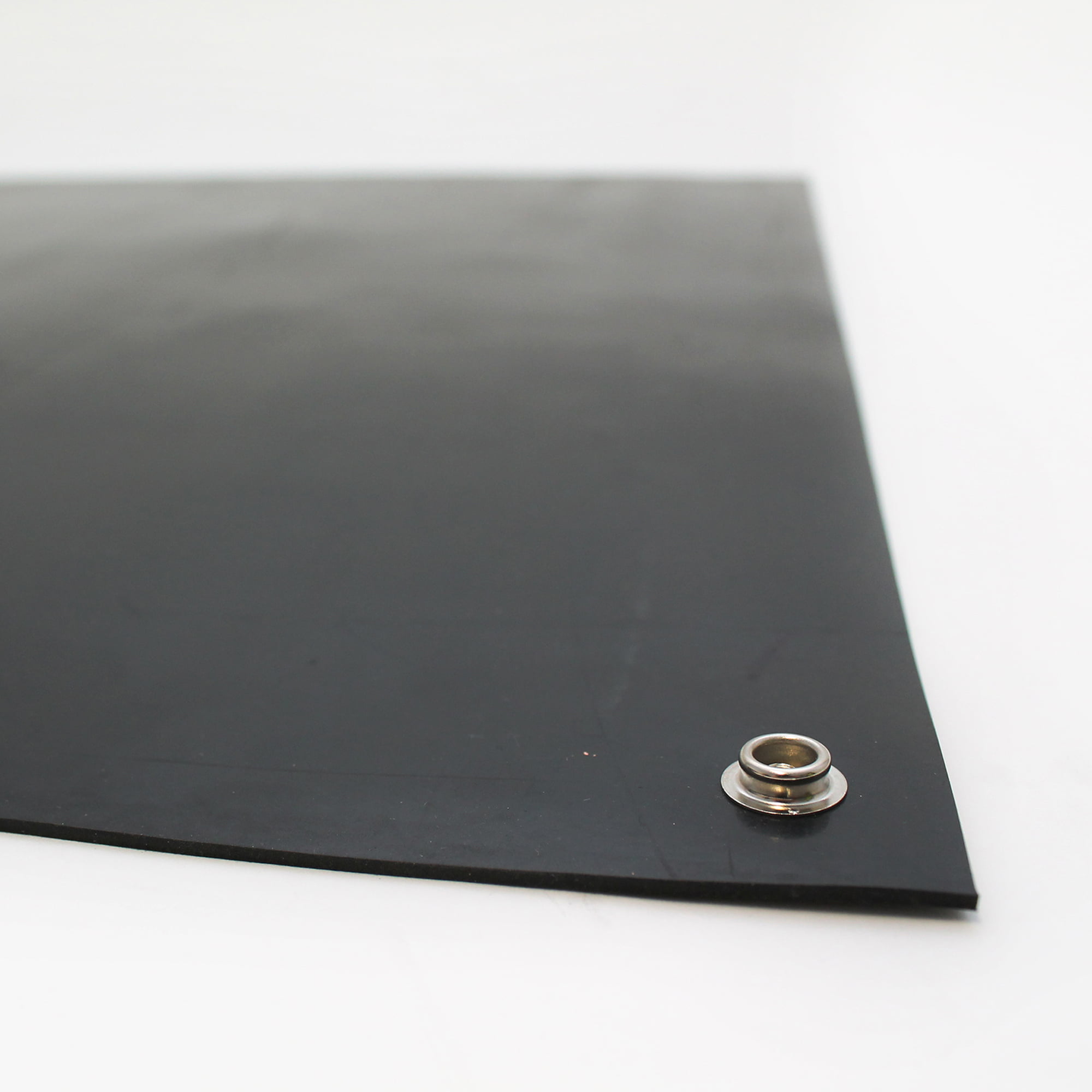

Benchstat and HR Matting from COBA Europe are good examples of ESD work surface mats. Static dissipative, they both feature a conductive buried layer to help protect components, meeting or exceeding IEC51349-5-1 resistance requirements.

Learn more about our Bench mat solution with two layer anti-static rubber matting

Learn more about our quality HR matting and ESD accessories workbench bundle

What is ohms?

When researching ESD matting, you will most likely encounter this symbol Ω, or ohm. Electrical resistance is measured in ohms (unit of resistance). There are Kiloms, Megaohms and Gigahoms. Resistance is measured as surface resistance, with readings in ohm/square.

ESD floor mats are very often manufactured from vinyl or rubber. Products can comprise two or three layers of materials, and can have for example, a buried conductive middle layer.

How to choose the correct ESD Mat?

Ensuring the right product is specified for the area in question is essential and ESD matting should never be confused with electrical switchboard matting. There is also a difference between static dissipative and anti-static flooring. Some flooring products are described as ‘anti-static’ while others are called ‘static dissipative’, so they are not one of the same. Floors described as anti-static, according to CFA guidelines, “limit generation of body voltage and hence reduce the risk of personal shock” and goes on to say, “it does not infer that the product has any capability to dissipate or conduct any charge”.

When it comes to ESD floor mats, COBAstat is a good example. While controlling ESD, it also offers the bonus of being extremely comfortable to stand, therefore having good anti-fatigue properties for operatives who have to stand for prolonged periods of time during their working day. It offers maximum performance when used in conjunction with a grounding wire and is suitable for any environment prone or sensitive to static build up. Similarly, there is Senso Dial, ESD approved floor mats which have anti-slip surface, while offering fatigue-relief and ESD protection.

In short, when choosing an ESD mat, make sure you know the specific requirements of your working environment and check out the resistance classifications carefully. Make sure you have all the necessary accessories to enable ESD mats to function properly and to ensure they are properly grounded. Follow the International ESD Standards, such as IEC 61340-5-1 for protection of electrostatic sensitive devices.

To find out more information about our ESD matting contact our team on +44 (0) 116 240 1088

Our team of experts are always ready to assist you with choosing the right mat, first time. If you are unsure of the correct ESD matting solution you require for your specific site, let us help you.